-

-

-

-

Contact Us

AR946 Photovoltaic Glass Coating Solution

Product Consulting

AR946 Photovoltaic Glass Coating Liquid Specification

Product Description:

AR946 coating anti-permeable liquid, used for photovoltaic glass anti-reflection, anti-reflection, improve the power generation efficiency of photovoltaic modules; at the same time, superior weather resistance, up to more than 25 years.

Advantage Features:

1. High transmittance gain, the average increase of 2.3~2.4%.

2. Pencil hardness 4H, good damp heat stability.

3. Good adaptability to moisture resistance and stable coating process.

4.40 ~ 60% RH humidity can be used, the rainy season and the seaside humid climate are to maintain good antireflection performance.

Application areas:

Photovoltaic glass cover plate, photothermal glass antireflection coating.

Process Guide:

1. Construction method: roller coating, ambient humidity RH40-60, temperature 20±2 ℃, dust-free grade 100000;

2. Design coating dry film thickness: 110nm;

3. Dilution: isopropyl alcohol dilution is recommended;

4. Drying: 200 ℃,1-2 minutes;

5. Tempering process: 720 ℃,2 minutes.

Performance indicators:

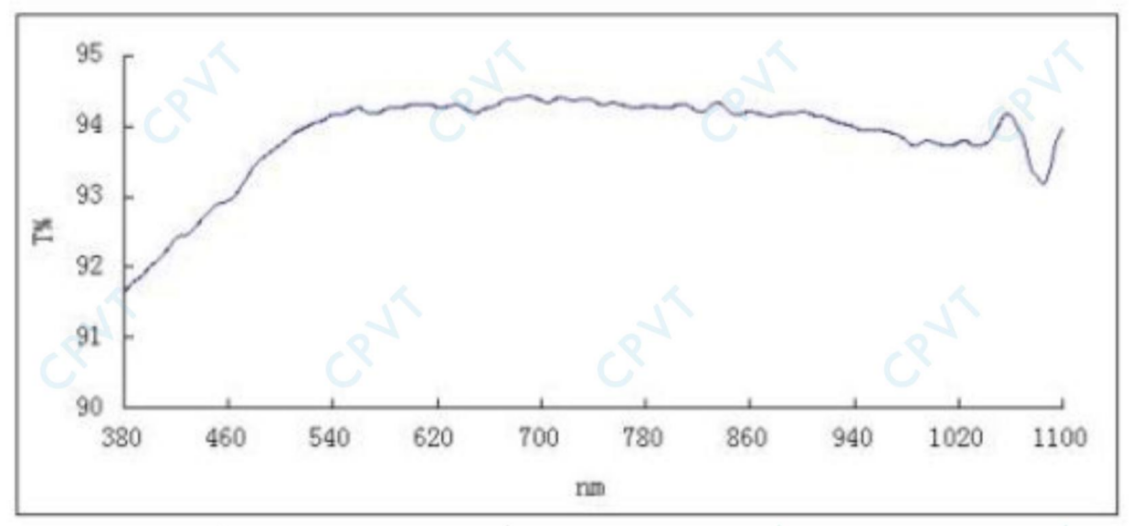

1. Transmittance curve

2. Performance parameters

|

Physical PerformanceProperties |

UnitUnit |

Test valueValue |

|

AppearanceAppearance |

NA |

Light white emulsion |

|

Specific GravitySpecific gravity |

g/mL@25℃ |

0.81~0.85 |

|

ViscosityViscosity |

cP@25℃ |

< 10 |

|

Solid contentSolid Content |

% |

3.8~4.2 |

|

pH |

pH |

4~6 |

|

increased permeabilityDT |

Transmission %(vs Blank) |

2.3~2.4 |

|

photovoltaic gainDW |

PV output %(vs Blank) |

~2.5 |

|

HardnessHardness |

1kg load/Mitsubishi Pencil |

≥ 3H |

|

Wear resistanceWiping Test |

200 cycles |

Pass |

|

1% (DS-10), 10000 cycles |

Pass |

|

|

Salt spray resistanceSalt Spray Test |

5% NaCl, 100 hrs |

Pass |

|

Damp heat agingHydrothermal Aging |

IEC61215, 1000 hrs |

Pass |

|

Resistance to moisture and freezingHumidity Freeze |

UL1703, 10 cycles |

Pass |

|

Thermal shockThermal Shock |

IEC61215, 200 cycles |

Pass |

|

Resistance to ultraviolet radiationQUV |

ASTM154-1, 1000 hrs |

Pass |

Packaging storage:

1. Packing: 25 liters plastic container, each net weight 20kg.

2. Storage: low temperature and dry environment, strictly sealed, protected from light; below 25 ℃, the shelf life is 6 months;

Note:

1. Should be in a low temperature dry environment, placed in a strictly sealed container, isolated from ultraviolet light, dark preservation;

2. Storage below zero may cause abnormal quality.

Limited Liability (please read carefully):

The Company ensures that the information provided above is accurate. However, because the conditions and methods of using our products are beyond our control, this information is not a substitute for customer testing to ensure that the products are safe, effective and fully satisfactory for a particular end use. We specifically disclaim any other express or implied warranties of fitness or merchantability for a particular purpose and are not responsible for any indirect or incidental damages.

Social Media

TikTok

Channels

Contact Information

Address: Unit 502, 5th Floor, West Side, No.12 Haijing East Road, Xiamen Area, China (Fujian) Pilot Free Trade Zone

Technical Services: 18030106835

E-mail: Support@winlight.tech

Company Phone: 0592-5201826

All Rights Reserved © 2024 Xiamen Winlight Technology Innovation Group Co., Ltd.