STC2520 hardening fluid

Product Consulting

STC2520 Hardening Fluid Instructions

Product Introduction:

STC2520 can make the PC sheet up to H(500g) surface hardness, lower rainbow pattern; excellent wear resistance, scratch resistance.

Advantage Features:

1. Good adhesion to PC;

2. The refractive index is matched with PC, and there is no multicolored pattern after strengthening;

3. Good abrasion resistance.

Application areas:

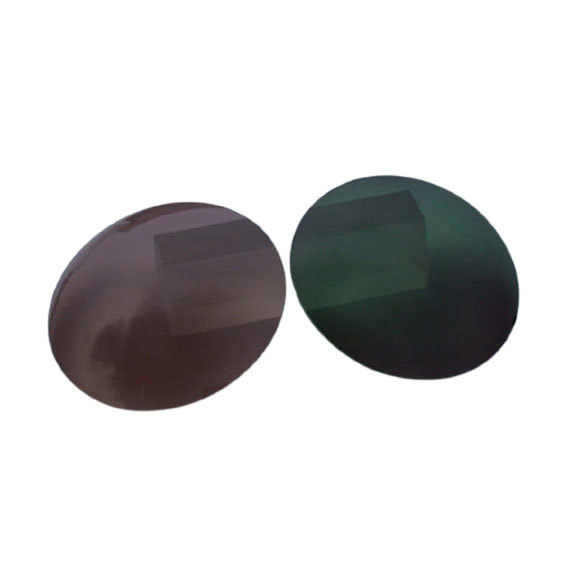

PC window lenses, sun lenses/optical lenses.

Process Guide:

|

Special Sex |

Typical value |

|

Environmental conditions |

20-25°C, 40-60% relative humidity |

|

Environmental cleanliness |

1000-10000 |

|

Airflow |

Filtration, Laminar Flow |

|

Coating temperature |

16-18°C |

|

coating filtration |

1-5 microns (absolute) |

|

Pull rate |

2mm/s |

|

Drying time/Temperature |

5-10minutes, infrared/60-70°C |

|

Curing conditions |

2hrs@120°C |

Data indicators:

1. Solution characteristics:

|

Characteristics |

Test Method |

Typical value |

|

Solid content |

30min @ 180 ℃ |

28-30 % |

|

Viscosity (cps) |

Rotational viscometer test at 25°C |

≤ 10 .0 |

|

Density (g/ml) |

Test of the specific gravity meter at 25 ℃ |

0.950-0.970 |

|

Solvent: Water, ethanol, propylene glycol methyl ether |

||

2. Cured coating characteristics:

|

Characteristics |

Test Method |

Typical value |

|

Layer thickness (One) |

thickness measuring instrument |

3-6 |

|

refractive index |

refractive index measuring instrument |

1.48 |

|

Scratch resistance |

6-bend lens 0000# steel wool load 200g test 20 back and forth |

≦ 5 scars |

|

Attach |

the hundred-grid method,3M Tape |

100% |

|

Boiled |

Boil in 80 ℃ water bath for 30min, 100-meter test |

100% |

Storage recommendations:

1. It is recommended to store in 2-5 ℃ environment;

2. This product contains alcohols, so pay attention to fire prevention during storage and use;

3. This product will react and deteriorate in contact with PVC, silica gel and carbon steel materials. Therefore, please use PTFE, polyethylene, polypropylene, stainless steel materials or containers when using and holding. Do not use PVC, silica gel and carbon steel materials.

Note:

1. This product cannot be mixed with other brands of strengthening liquid. Before using this brand of strengthening liquid, the container should be fully cleaned.,Pipes, filters;

2. In order to ensure that there is no crystal point on the surface, the strengthening solution needs to be filtered with 1um or 2um polypropylene (PP) folded filter element for 12 hours before it can be used for the first time. In the production process, each time the strengthening solution is added, it needs to be added in the auxiliary tank. After addition, it also needs to be continuously circulated and filtered for more than 2 hours before it can be produced again;

3. Before coating, the lens should be cleaned and the room should be clean, and the cleanliness should be between 1000-10000. In the production process, due to the volatilization of the solvent, the viscosity of the strengthening solution will gradually increase, which can be diluted with isopropanol or ethanol, as long as the solid content is controlled at 28-30between%.

Limited Liability (please read carefully):

The Company ensures that the information provided above is accurate. However, because the conditions and methods of using our products are beyond our control, this information is not a substitute for customer testing to ensure that the products are safe, effective and fully satisfactory for a particular end use. We specifically disclaim any other express or implied warranties of fitness or merchantability for a particular purpose and are not responsible for any indirect or incidental damages.