State-Level High-Tech Enterprise

Focus On Optical Plastic/Glass Functional Coating

Xiamen Winlight Technology Innovation Group Co., Ltd

It is a science and technology venture capital group company relying on nanotechnology, nano-oxide thin film technology, optical coating technology and precision coating technology, and extending the industrial chain through the application and development of key technologies. The group consists of five divisions: nano-materials division, organic monomer division, polymer materials division, functional glass division and new energy division. Each division undertakes the functions of project incubation and personnel training. The group has the following companies:

Xiamen Winlight Optical Coating Technology Co., Ltd.

It is a company that develops organic-inorganic hybrid between nano-oxide and organic silicon, and realizes the functions of blocking ultraviolet light, visible light and infrared light through nano-oxide, and increasing transparency and absorption;

Optical coating for optical plastic, glass surface;

Refractive index adjustable coating 1.30-1.90 refractive index;

Hydrophilic anti-fog, AF anti-fouling hydrophobic coating;

Infrared barrier coating;

Infrared cut-off (IR-CUT) coating;

Radiation cooling coating.

Xiamen Winlight Photoelectric Technology Co., Ltd

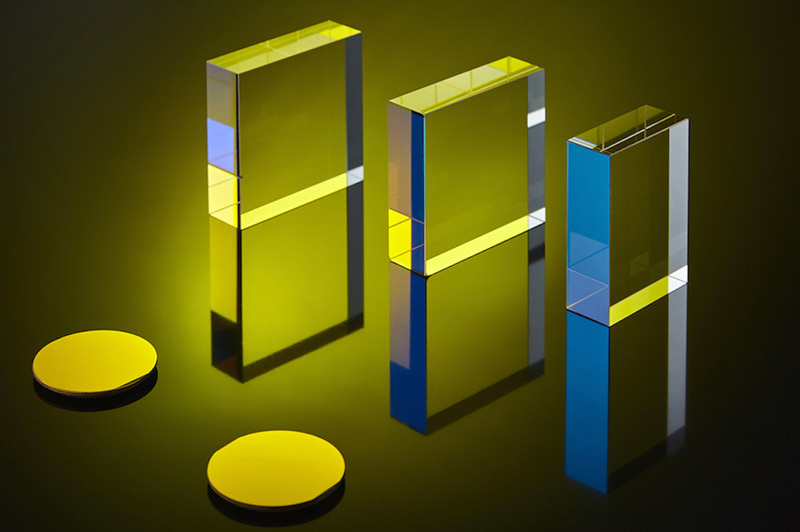

Main business: AR anti-reflection and anti-reflection glass, semi-reflective and semi-transparent glass AF glass, anti-fog glass, ITO conductive glass, infrared cut-off glass, antibacterial glass, etc. for mobile phones, notebooks, smart homes, security, education tablets and other industries.

Division

Functional Glass Division-Glass with special functional coating

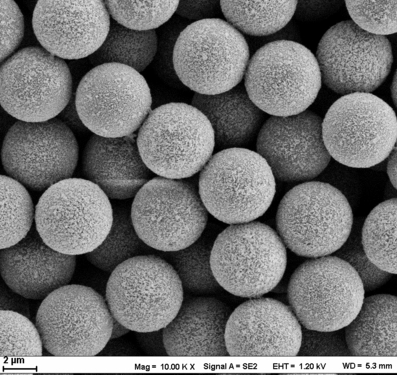

Nanomaterials Division-water or alcohol dispersion or powder of nano-silica, nano-titanium dioxide, nano-zirconium dioxide, nano-cesium tungsten bronze.

Organic monomer division-polyurethane waterborne special chain extender DHPS, DHBS, other organic monomers.

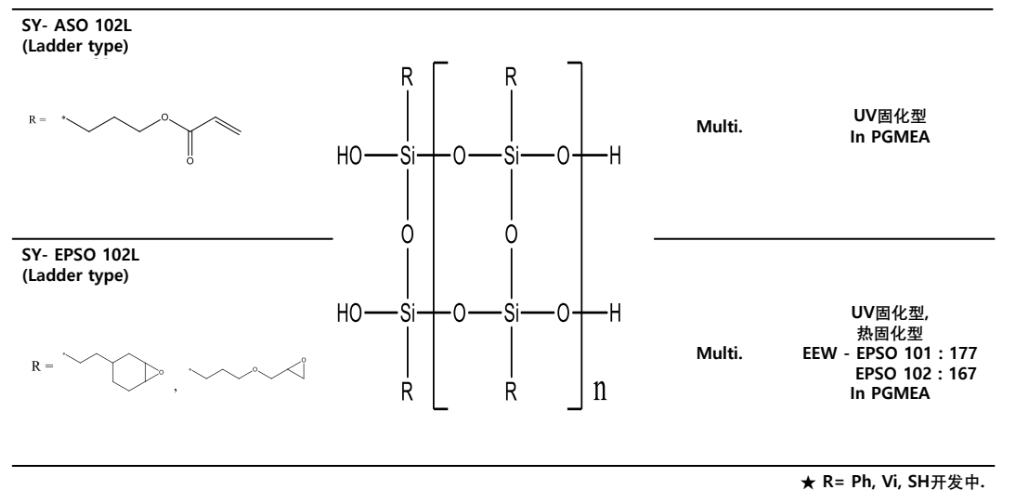

Polymer Materials Division-silicone resin, polyurethane resin, emulsion, acrylic resin and emulsion, IMD functional film.

* Nanotechnology is the synthesis of 100nm below the oxide and dispersed in water or alcohol or acrylic monomer and polymer resin technology

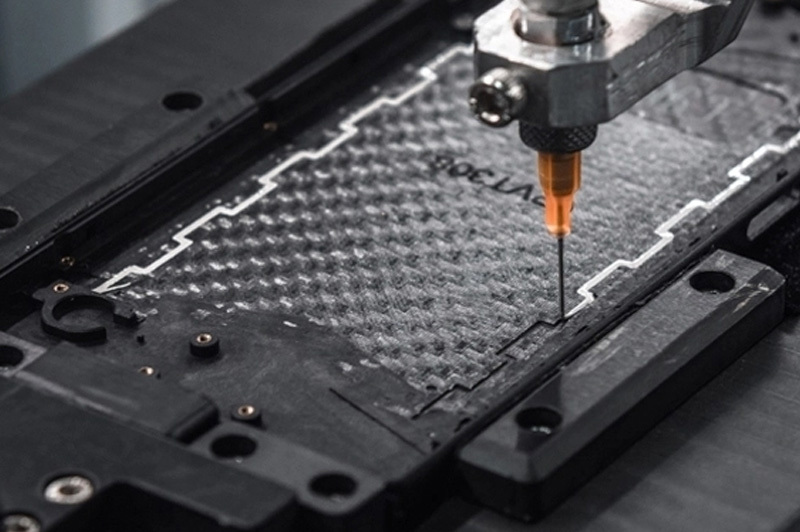

* Precision coating technology is the technology of coating functional coatings on functional films and glass with nanoscale precision.

Technology R & D

Xiamen Winlight Science and Technology Innovation Group Co., Ltd. pays attention to the construction of technology platform and product platform, introduces IDDOV new product research and development control process, and cooperates with Sichuan University, Xiamen University, Zhengzhou University and the three marine universities and research institutes to realize the transformation from technology development to product development.

Product Center

A technology venture capital group company that relies on nanotechnology, nano-oxide film technology, optical coating technology, and precision coating technology, and develops key technology applications to extend the industry chain.

Application Areas

Winlight Company pays attention to building platform technology and establishes an innovative product research and development team. The laboratory has complete experimental equipment and testing instruments. It cooperates with the three marine universities, Xiamen University, Sichuan University and other universities to realize the exchange and sharing of technology platforms.

News

Gain More Growth Opportunities With Customers

How to maintain AR coated lenses

Aug 21,2023

New York's "Plastic Bag Ban" goes into effect in March!

Aug 21,2023

Winlight Optical Develops Research Hot Material POSS Polyhedral Oligosiloxane

Aug 21,2023

Aug 21,2023

2023-08-21

Various types of IMD in-mold decoration process introduction

2023-08-21

Nano titanium dioxide sol, high purity, multi-functional nano-materials

2023-08-21

Winlight takes you to understand the principle of bidding farewell to fogging

2023-08-21